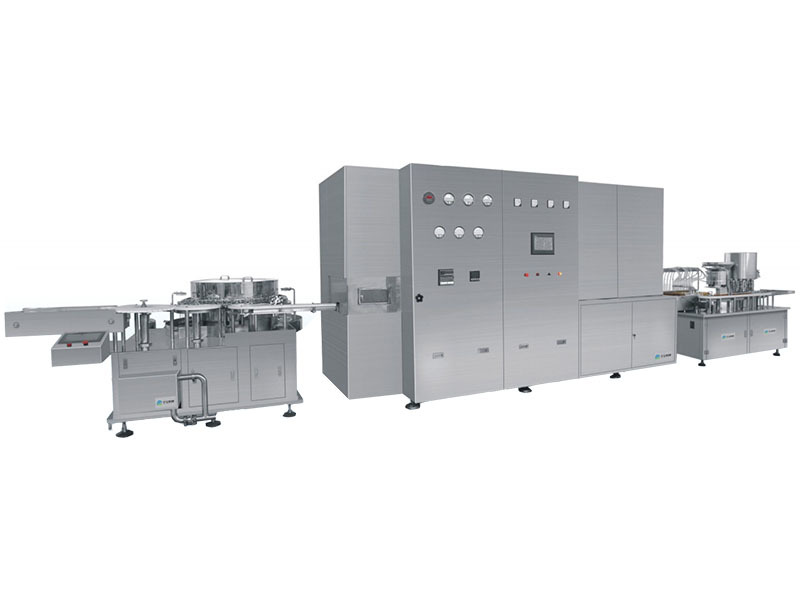

5-50ml oral liquid filling production line

Classification:

Summary:

The touch screen can show the running dynamic of each single machine, thewater pressure, pressure, pressure and temperature of each control point, eachswitch state and fault display, fault self diagnosis and fault analysis and eliminationmethod, which make the whole production process automatic control. The line hasthree machine self control balancing device to ensure the balance and reliability ofproduction..Choose SlEMENS according to customer's needs.

Product Details

- Product Description

-

The touch screen can show the running dynamic of each single machine, thewater pressure, pressure, pressure and temperature of each control point, eachswitch state and fault display, fault self diagnosis and fault analysis and eliminationmethod, which make the whole production process automatic control. The line hasthree machine self control balancing device to ensure the balance and reliability ofproduction..Choose SlEMENS according to customer's needs.

Equipment Features

1. The bottle washing machine adopts mechanical hand clamping bottle, and issuitable for bottles of various specifications.

2. Washing bottle adopts tracking and inserting water, air washing quality is high,saving water.

3. The bottle washing bottle adopts the integral import synchronous belt, andconnects the bottle pulling block to deliver the oral liquid, which runs stably andreliably.

4. The oven is heated by infrared heating tube and double heated by stainlesssteel heating pipe.

5. The filling and covering machine can be selected with the ceramic pump andthe stainless steel pump.

6,Bottle free filling, bottle free cover function.7. Wash the crude washing water and separate the water pipe from the clean waterwithout cross contamination.

8. A buffer block is added to the bottle screw of the bottle washing machine, and aprotective screw is arranged to reduce the function of bottle breaking.

9, The whole line adopts PLC total control, frequency converter and touch-screencontrol technology,and runs stably and reliably.

Technical parameters

Application 5-50ml Production capacity 200-600 bottles/min loading error ≤ ± 2% Qualified Cap Crimping Rate ≥ 99% Weight 8000kg Dimension 9500*2100*2400mm

Key words:

bottle unpacking machine | bottle washing machine | filling machine | oral liquid filling production line

Product Recommend

5-50ml oral liquid filling production line

Classification:

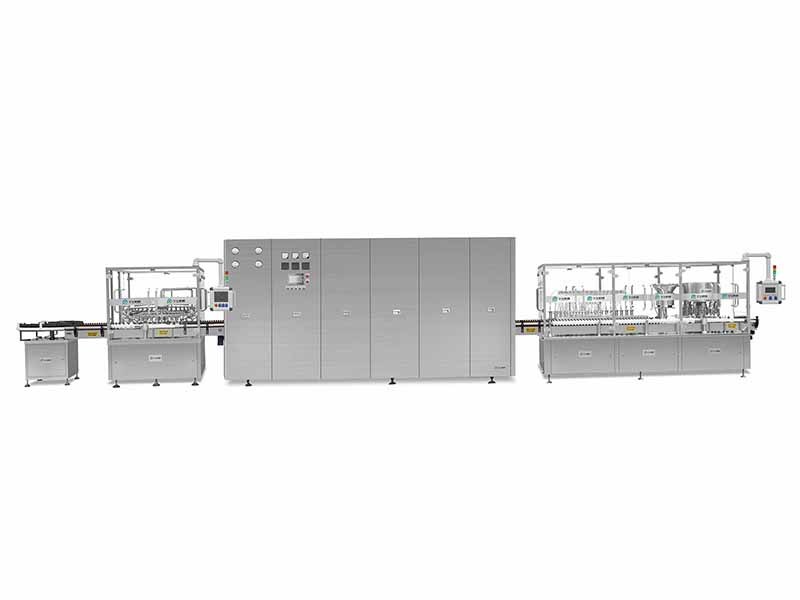

20-200ml oral liquid filling production line

Classification:

Plastic Bottle Filling Production Line

Classification:

Welcome to leave a message for consultation