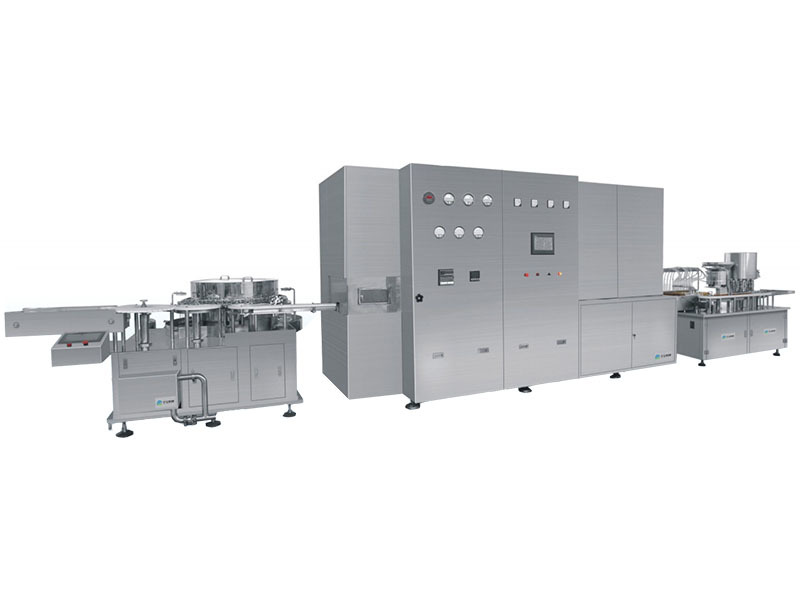

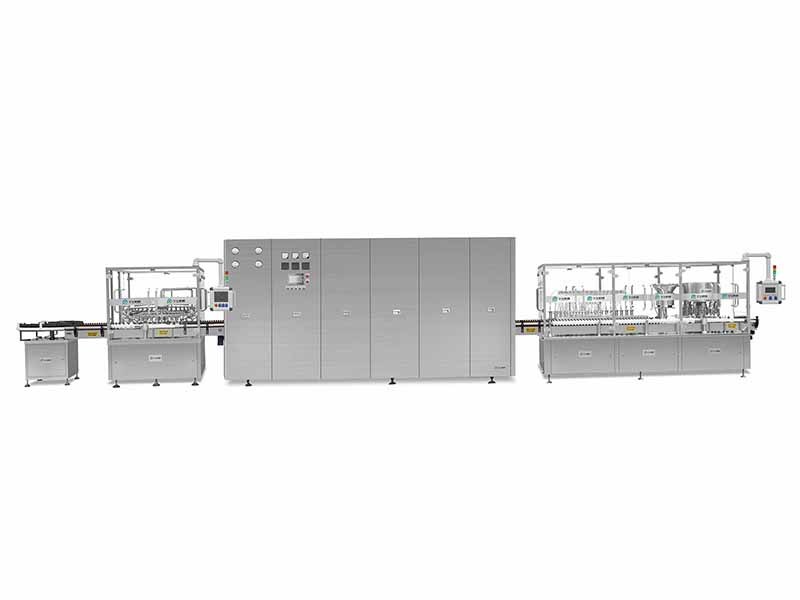

20-200ml oral liquid filling production line

Classification:

Summary:

Product Details

- Product Description

-

Equipment Features

1. This production line suitable for 20-100ml metal screw thread cap glass bottleoral liquid Washing, Drying, Filling and capping(Roll).

2. Production line composed by Washing machine, Tunnel oven, Liquid filling andcapping(roll) machine, Can be connected for production line or stand-alone.

3.The technological process: Bottle feeding, Washing bottle, Dry and sterilization.Filling and capping(roll).

4. Widely used in glass bottles of oral liquid, especially capping(roll) metal screwthread cap is our company patent structure, screw thread neat and smooth,Equipment performance stable, Operation is very simple.5.According to customer technological requirements configuration can satisfydifferent specifications and production speed.

Technical parameters

Product No. KGF10-10 KGF16-12 Applicable specification 20-200ml 20-200ml Production Capacity 100-120 bottles/min 150-200 bottles/min Filling accuracy ±1-2% ±1-2% Water pressure and water consumption 0.3-0.5mpa,0.6-1m3/h 0.3-0.5mpa,0.6-1m3/h Power supply 380/220v,42.5kw 280/220v,45kw Purify compressed air pressure and air consumption 0.6-0.8mpa,10-45m3/h 0.3-0.8mpa,10-45m3/h Exhaust volume 2600m3/h 2800m3/h Weight 5000kg 6000kg Dimension 11000*1550*2000mm 15000*1750*2000mm

Key words:

bottle unpacking machine | bottle washing machine | filling machine | oral liquid filling production line

Product Recommend

5-50ml oral liquid filling production line

Classification:

20-200ml oral liquid filling production line

Classification:

Plastic Bottle Filling Production Line

Classification:

Welcome to leave a message for consultation