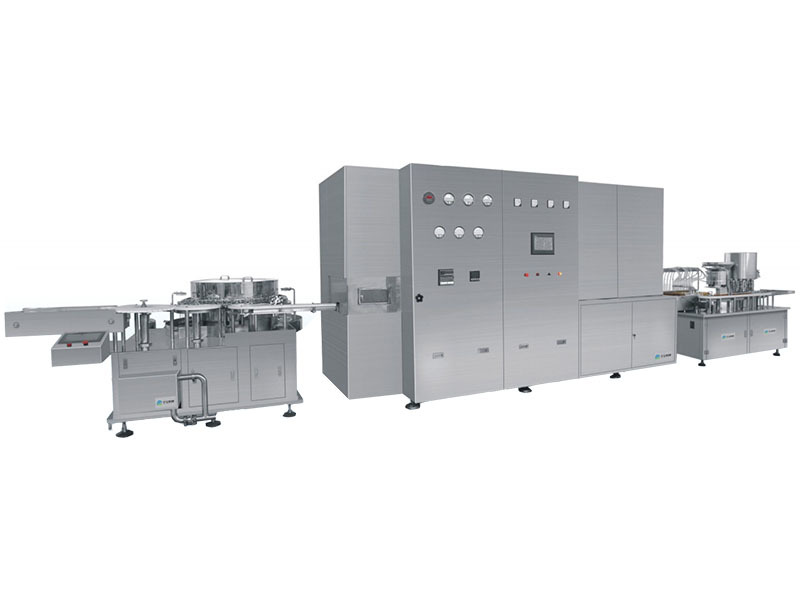

YQ-PGX-100 Automatic spray filling production line

Classification:

Summary:

This production line is suitable for filling/rotary nozzle/labeling of antibacterial sprayplastic bottles; lt can complete processes such as bottle sorting, filling, upper nozzlerotation, automatic upper nozzle rotation, and automatic labeling. The machine isequipped with dual track bottle filling, electromagnetic vibration for capping, clamppositioning for capping, upright pre rotation, and three claw torque capping; it hasfunctions such as bottle blockage alarm, shortage of bottles, materials, and caps alarmshutdown, and no capping when there are no bottles. Replacing the specification partscan be used for filling various bottle types.

Product Details

- Product Description

-

This production line is suitable for filling/rotary nozzle/labeling of antibacterial sprayplastic bottles; lt can complete processes such as bottle sorting, filling, upper nozzlerotation, automatic upper nozzle rotation, and automatic labeling. The machine isequipped with dual track bottle filling, electromagnetic vibration for capping, clamppositioning for capping, upright pre rotation, and three claw torque capping; it hasfunctions such as bottle blockage alarm, shortage of bottles, materials, and caps alarmshutdown, and no capping when there are no bottles. Replacing the specification partscan be used for filling various bottle types.

Purpose

This production line is suitable for filling/rotary nozzle/labeling of antibacterial sprayplastic bottles; lt can complete processes such as bottle sorting, filling, upper nozzlerotation, automatic upper nozzle rotation, and automatic labeling. The machine isequipped with dual track bottle filling, electromagnetic vibration for capping, clamppositioning for capping, upright pre rotation, and three claw torque capping; it hasfunctions such as bottle blockage alarm, shortage of bottles, materials, and caps alarmshutdown, and no capping when there are no bottles. Replacing the specification partscan be used for filling various bottle types.

Main Technical Parameters

Filling volume 20-100ml Production Capacity 60-80 bottles/min Loading accuracy ±2% Number of filling heads 2 head PCS Number of capping heads 2 head PCS Host power 5KW 220V 50HZ Capping method Three claw magnetic torque(adjustable) Cover method Pneumatic positioning upper cover Filling pump material 316 stainless steel plug pump(8 pumps) Qualification rate of rotary cap ≥ 99% Dimension 3320*2000*1600mm

Key words:

bottle unpacking machine | bottle washing machine | filling machine | oral liquid filling production line

Product Recommend

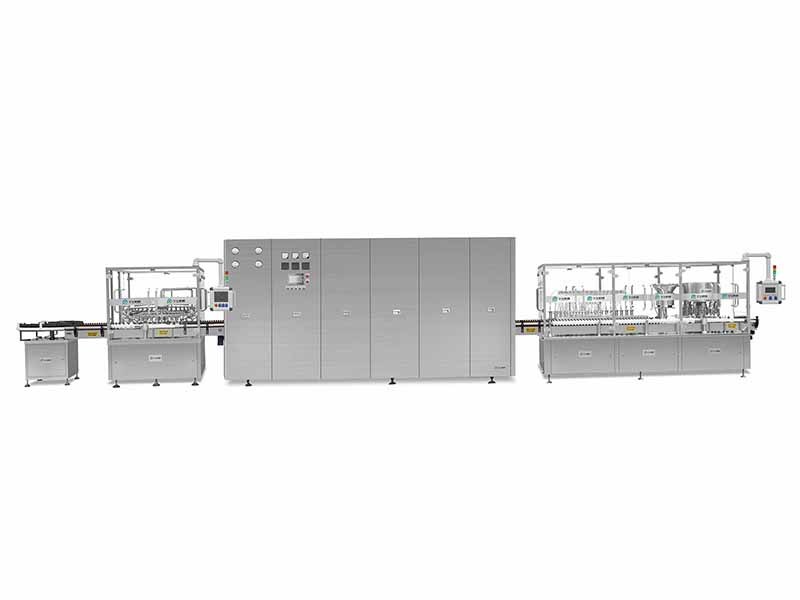

5-50ml oral liquid filling production line

Classification:

20-200ml oral liquid filling production line

Classification:

Plastic Bottle Filling Production Line

Classification:

Welcome to leave a message for consultation