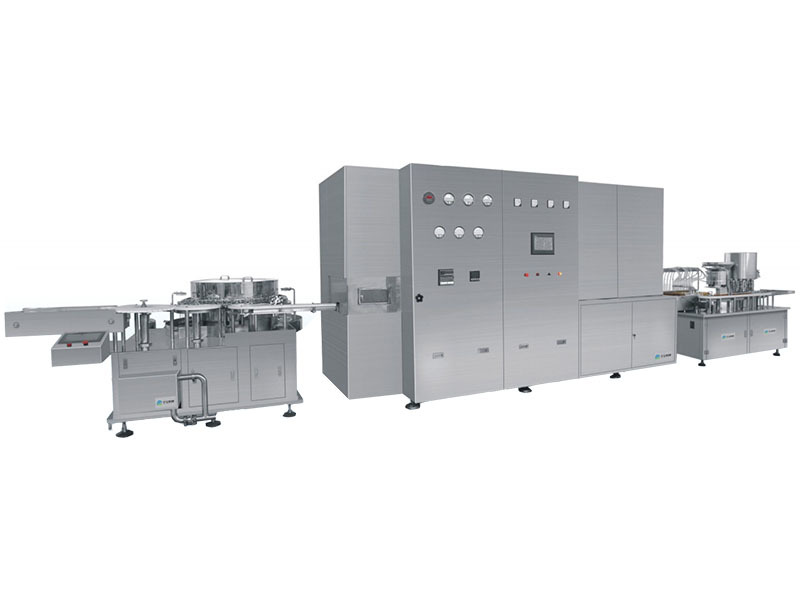

ROGNX-GS High speed eye drop filling and capping machine

Classification:

Summary:

The bottle enters the filling section after being buffered by the supplybottle, and is filled on the conveyor belt using a 6-head servo stainless steelceramic pump. After filling, it enters the stoppered and capped section; Theplugging and capping part adopts electromagnetic oscillation plugging andcapping, and advanced vacuum rotary plugging method is used for pluggingand capping. Finally, perform a rotary capping process using an advancedmagnetic capping system.

Product Details

- Product Description

-

The bottle enters the filling section after being buffered by the supplybottle, and is filled on the conveyor belt using a 6-head servo stainless steelceramic pump. After filling, it enters the stoppered and capped section; Theplugging and capping part adopts electromagnetic oscillation plugging andcapping, and advanced vacuum rotary plugging method is used for pluggingand capping. Finally, perform a rotary capping process using an advancedmagnetic capping system.

Working principle

The bottle enters the filling section after being buffered by the supplybottle, and is filled on the conveyor belt using a 6-head servo stainless steelceramic pump. After filling, it enters the stoppered and capped section; Theplugging and capping part adopts electromagnetic oscillation plugging andcapping, and advanced vacuum rotary plugging method is used for pluggingand capping. Finally, perform a rotary capping process using an advancedmagnetic capping system.

Technical parameters

Content Description Source 380V 50HZ Bottle Specifications 5ml-15ml plastic bottle Filling pump Siemens servo system Total power 5kw Production capacity Yield 150-200 bottles/min Filling volume error ±0.5% Single machine noise ≤ 70dB Vacuum pressure Pressure 600pa Weight About 1000kg Dimension 3800*1460*1650mm (specifically designed with actual bottles)

Key words:

bottle unpacking machine | bottle washing machine | filling machine | oral liquid filling production line

Product Recommend

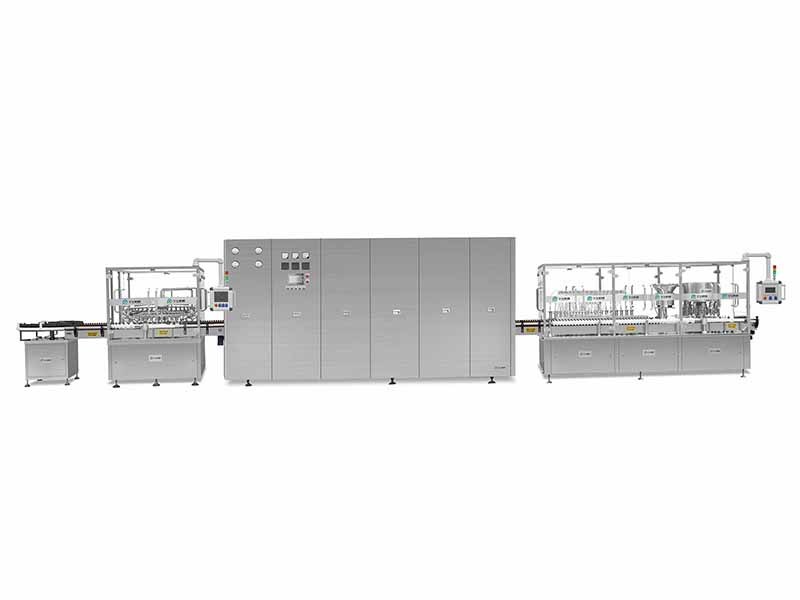

5-50ml oral liquid filling production line

Classification:

20-200ml oral liquid filling production line

Classification:

Plastic Bottle Filling Production Line

Classification:

Welcome to leave a message for consultation