YQ-LX Vertical Bottle Washer

Classification:

Summary:

The YQ-LX type ultrasonic bottle washing machine is used for cleaning 10-30diameter outer diameter, Xilin bottle and infusion bottle.

Product Details

- Product Description

-

The YQ-LX type ultrasonic bottle washing machine is used for cleaning 10-30diameter outer diameter, Xilin bottle and infusion bottle.

The YQ-LX type ultrasonic bottle washing machine is used for cleaning 10-30diameter outer diameter, Xilin bottle and infusion bottle.

It is simple and practical to use the bulk into the bottle.

The use of mechanical hand bottle can be applied to various specifications bottles.

Use tracking and inserting water and steam to ensure low quality andlow consumption of water and steam.

Using PLC program control, touch screen function display andoperation.

Equipment Features

The bottle of the bulk is entered into the ultrasonic cleaning tank by the bottleof the bottle. After about 30-80 seconds ofultrasonic cleaning, the bottle is sent tothe lifting dialing wheel to enter the big drum and is clamped by the manipulatorthen the 180 degree bottle mouth is turned down, and as the large turntable isrotated clockwise. in the lower part of the large tumtable, the 6 assembly of thewater spray (steam) tube is followed by the injection of a spray(steam) tube. Theinjection needle is inserted into the bottle to cary out two cycles of water, acompressed air, a fresh water, and a two time to purify the compressed air. At thesame time, the water vapor is also washed outside the bottle to complete thecleaning process of the bottle. After the bottle is washed, the bottle is washed bythe manipulator. The bottie is tumed right (the bottle is upwards) and the bottle issent to the tunnel oven by the dial wheel, The bottle washing machine controls theproduction capacity of the bottle washing machine by means of frequencyconversion speed control, and controls and adjusts the sequence coordination ofeach process of the bottle washing process through the PLC program.

Key words:

bottle unpacking machine | bottle washing machine | filling machine | oral liquid filling production line

Product Recommend

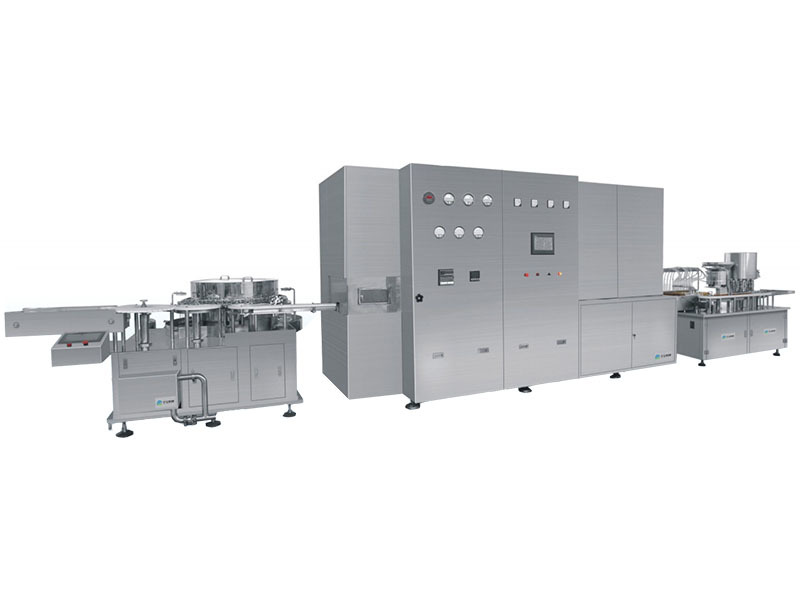

5-50ml oral liquid filling production line

Classification:

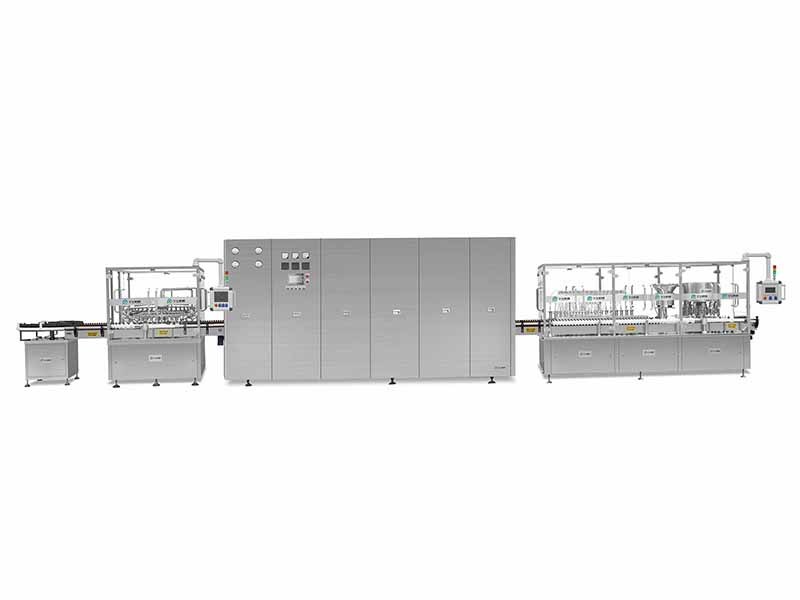

20-200ml oral liquid filling production line

Classification:

Plastic Bottle Filling Production Line

Classification:

Welcome to leave a message for consultation