Streamlining Production: TheOral Liquid Filling Line Revolution

Release time:

2025-11-18 02:12

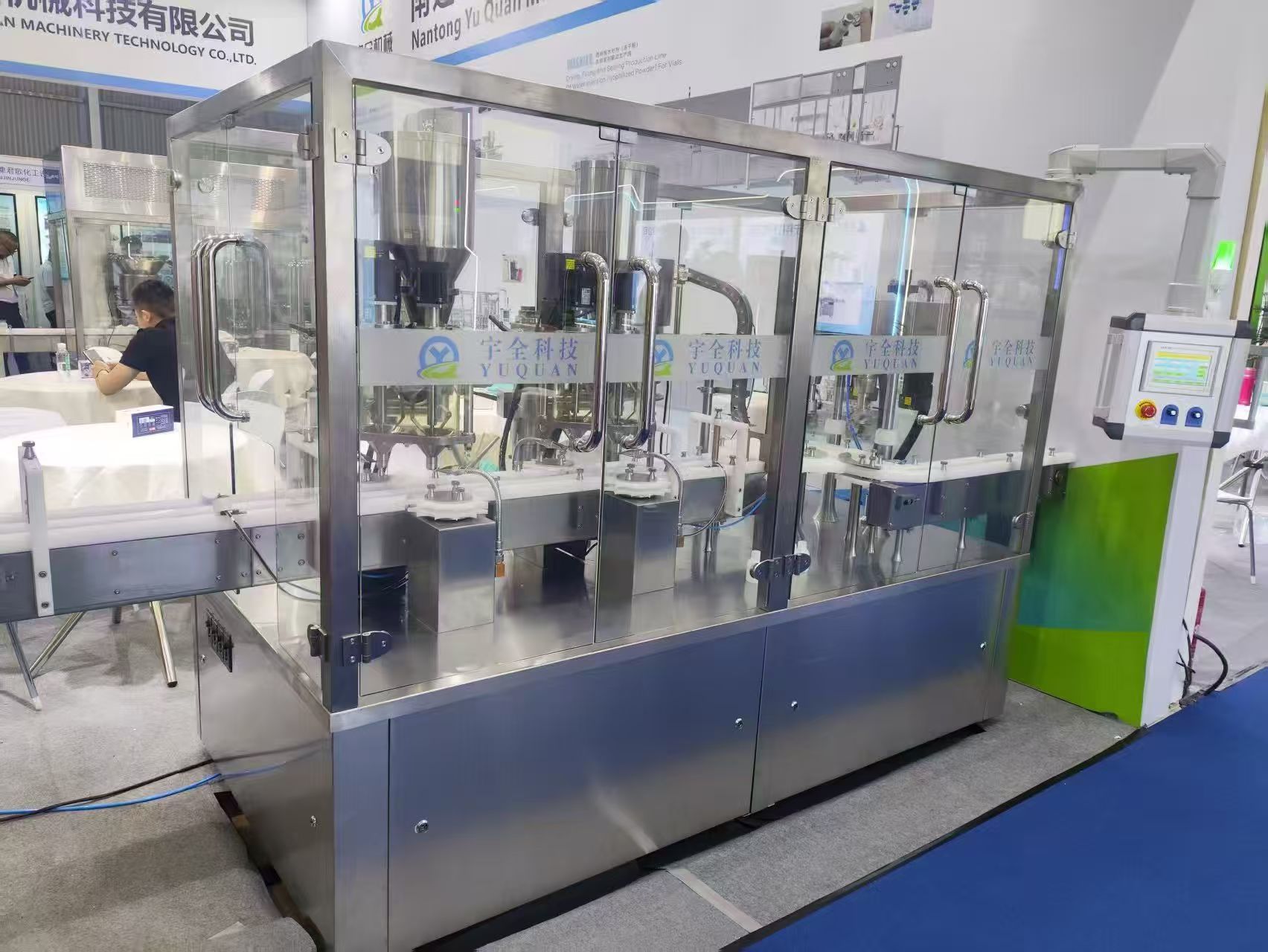

Introduction to theOral Liquid Filling Line

In the fast-paced world of pharmaceuticals and beverages, efficiency is key. Enter the Oral Liquid Filling Line—a game-changer that transforms how liquid products are packaged. This marvel of modern engineering not only boosts productivity but also ensures accuracy, quality, and hygiene. Interested? Let's dive into what makes this line a must-have!

What is anOral Liquid Filling Line?

Simply put, anOral Liquid Filling Line is a specialized assembly line designed for the automatic filling of liquid products into bottles, vials, or other containers. Think of it as the backbone of any liquid production facility, where speed meets precision. These lines are equipped with advanced technologies that allow them to handle various viscosities, from water-thin syrups to thicker medicinal liquids.

Key Features of theOral Liquid Filling Line

- High Efficiency: With the ability to fill hundreds of containers per minute, this line keeps production flowing smoothly.

- Flexible Configuration: Whether you're filling small vials or large bottles, theOral Liquid Filling Line can be tailored to your needs.

- Precise Measurement: Advanced sensors and automation ensure that each container is filled to the exact specifications, minimizing waste and maximizing quality.

- Easy Maintenance: Most models are designed for quick cleaning and maintenance, which reduces downtime and keeps your operation running smoothly.

Why Invest in anOral Liquid Filling Line?

Now, you might be asking yourself, "Why should I jump on the bandwagon?" Well, let's break it down:

- Cost-Effective: While the initial investment might seem steep, the long-term savings from reduced labor costs and increased output are undeniable.

- Quality Assurance: In an industry where quality is non-negotiable, having an automated system minimizes human error and enhances product integrity.

- Regulatory Compliance: ManyOral Liquid Filling Lines are designed to meet stringent industry regulations, giving you peace of mind.

The Process: How It Works

Picture this: theOral Liquid Filling Line hums to life as raw liquid is pumped into the system. The following steps occur:

- Preparation: The liquid is prepared and stored in tanks, ready for filling.

- Filling: Automated machines fill containers with precision, ensuring each one meets the desired volume.

- Capping: After filling, the containers are capped and sealed to maintain freshness and prevent contamination.

- Labeling: Finally, labels are applied, providing necessary information to consumers.

Real-World Applications

The versatility of theOral Liquid Filling Line extends across various industries. Here are a few:

- Pharmaceuticals: Filling bottles with liquid medications, ensuring accuracy and compliance.

- Beverages: From juices to flavored waters, the line efficiently fills and packages drinks for consumers.

- Cosmetics: Filling bottles with liquid beauty products, meeting high standards of quality and presentation.

Conclusion

In a nutshell, theOral Liquid Filling Line is a vital cog in the machinery of modern production. It enhances efficiency, ensures quality, and meets the demands of today's market. If you're looking to streamline your operations, investing in this technology might just be the best decision you'll make. Don't get left behind—embrace the future of liquid packaging today!

Oral Liquid Filling Line

Latest News