Unlocking the Secrets of theOral Liquid Filling Line

Release time:

2025-11-11 02:48

Introduction toOral Liquid Filling Lines

Ever wonder how your favorite syrups, cough medicines, or liquid vitamins get packed so neatly into bottles? Well, the magic happens thanks to the Oral Liquid Filling Line! This nifty piece of machinery is the unsung hero of the pharmaceutical and food industries, ensuring that every drop is precisely measured and sealed. Let's dive into some common questions about these fascinating filling lines!

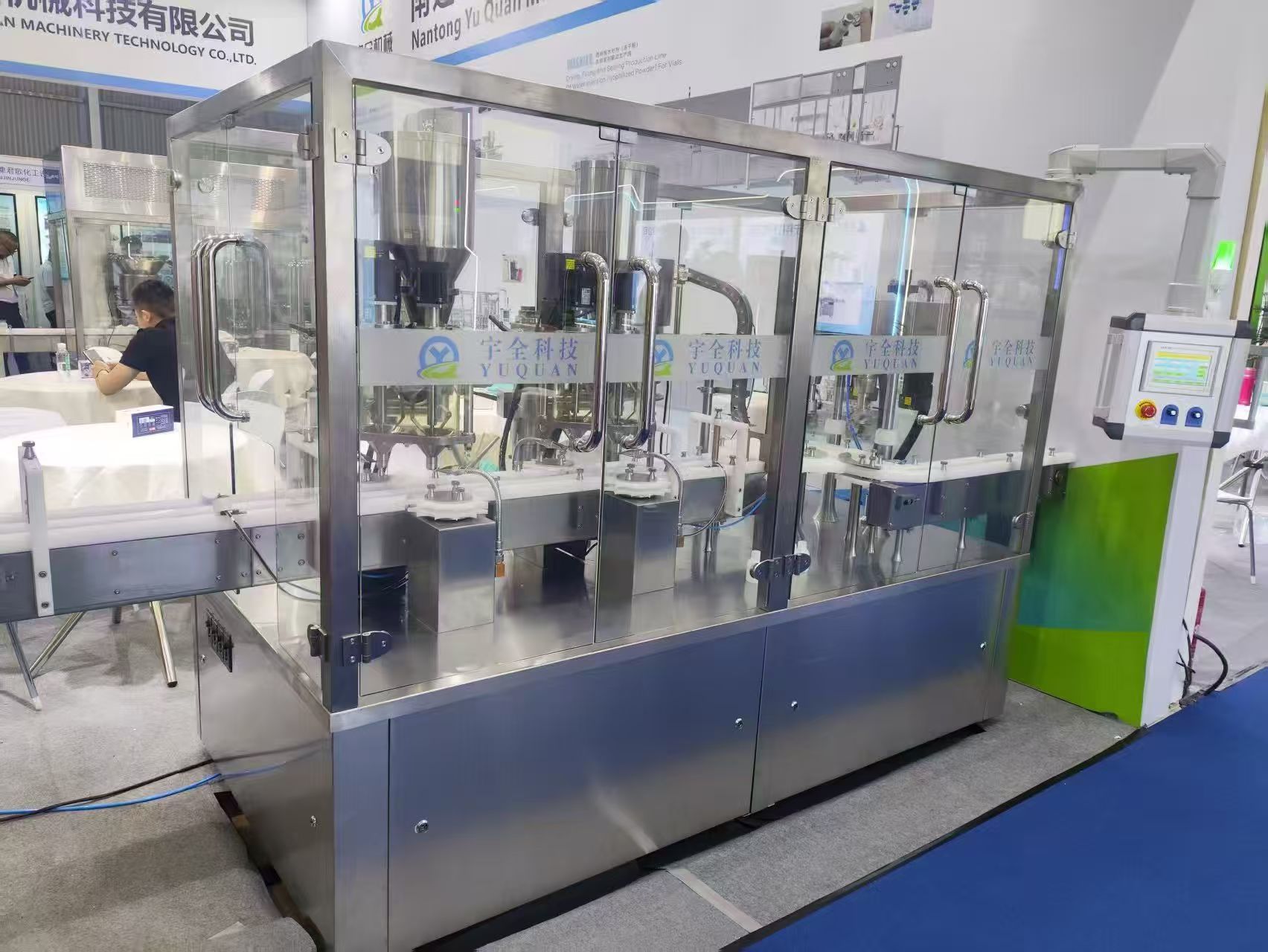

What Exactly is anOral Liquid Filling Line?

In simple terms, an Oral Liquid Filling Line is a system designed to fill liquid products into containers such as bottles, vials, or pouches. It's a blend of technology and precision that ensures the right amount of liquid is dispensed without spills or waste. Think of it as a well-oiled machine that works tirelessly to keep our medicine cabinets stocked!

How Does It Work?

Ah, the million-dollar question! An Oral Liquid Filling Line typically includes several components:

- Filling Machines: These are the heart of the operation, where the actual filling occurs.

- Conveyors: They transport the containers to and from different stations.

- Capping Machines: After filling, these machines secure the caps to ensure everything is airtight.

- Labeling Machines: Finally, the bottles get labeled with all the necessary information.

In a nutshell, it's a seamless flow that transforms raw ingredients into a ready-to-sell product!

What Are the Advantages of Using anOral Liquid Filling Line?

Now, let's talk benefits! Here's why companies invest in these systems:

- Efficiency: Speed up production and reduce labor costs.

- Precision: Minimize errors in filling, ensuring each bottle is just right.

- Sanitation: Automated processes limit human contact, enhancing hygiene.

- Versatility: Capable of handling various liquid types and container sizes.

Who wouldn't want that kind of reliability?

What Common Issues Might Arise?

As with any technology, hiccups can occur. Here are a few common problems you might encounter:

- Clogged Nozzles: Sometimes, the filling nozzles can get jammed, causing delays.

- Incorrect Fill Levels: If things aren't calibrated right, you might end up with half-filled bottles!

- Leaks: A faulty seal can lead to messy situations, and nobody wants sticky floors.

But don't fret! Most issues can be resolved with routine maintenance and checks.

How Do You Choose the RightOral Liquid Filling Line?

Choosing the right line can feel like finding a needle in a haystack, but here are some tips:

- Assess Your Needs: Determine the scale of your production and types of liquids.

- Research Brands: Look for reputable manufacturers with solid customer reviews.

- Consider Budget: Balance quality with affordability; you don't want to break the bank!

With a bit of research, you'll find the perfect fit for your operation!

Conclusion

So there you have it—an insider's look at the Oral Liquid Filling Line! Whether you're a manufacturer or just curious about how products reach your shelf, understanding these systems can provide a whole new appreciation for the process. Next time you crack open a bottle of cough syrup, you'll know just how much thought and technology went into that little container!

Oral Liquid Filling Line

Latest News