How to Solve the Frequent Faults in the Use of Powder Filling Machine

Release time:

2024-08-08 09:24

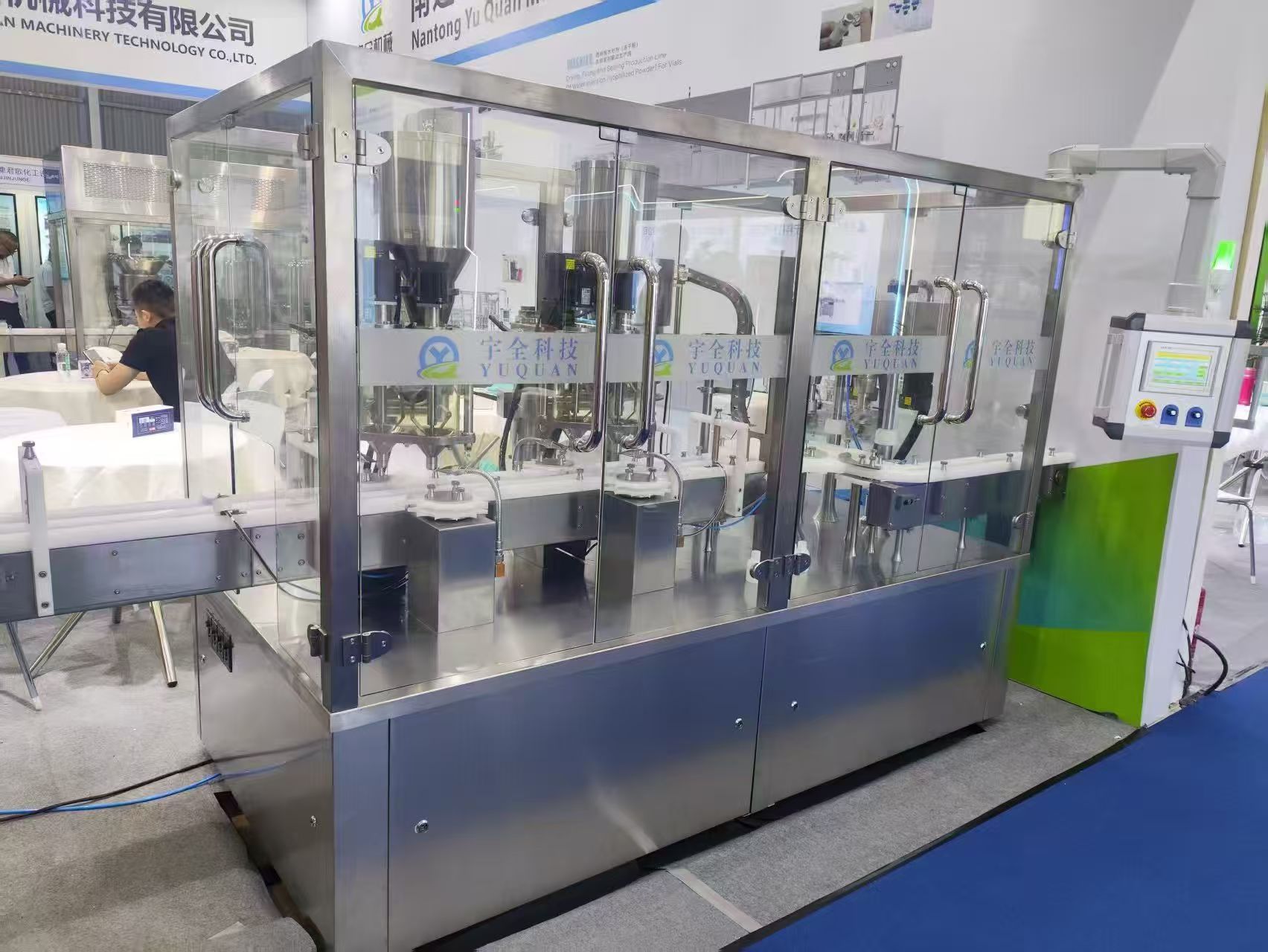

At present, there are more and more types of powder filling machines on the market, and the fields of application are becoming wider and wider, and consumers are more and more aware of them. For example, the food, medicine, hardware, daily chemical and other industries in our daily life can not leave the powder filling machine. With the progress of science and technology and the development of the times.

Powder filling machine from the previous level of relatively backward state development to today's high quality, high precision, high level of automation, along the way through a lot of twists and turns, and businesses only in the powder filling machine to have the understanding of the purchase, and easier to solve the problems in the use of the process.

Principle features:

1. Powder filling machine is generally the use of machine, electricity, light, instrument in one, single-chip microcomputer control equipment, with automatic quantitative, automatic filling, automatic adjustment of measurement error and other functions

2. Using stepper motor and electronic weighing technology, so it has high precision.

3. The same quantitative filling machine installed through the electronic scale keyboard adjustment and replacement of different specifications of the feeding screw continuously adjustable, more convenient to use.

4. Powder-like and granular materials with certain fluidity can be suitable for quantitative packaging of various powders such as cans, bags, bottles, etc. This proves that its scope of application is relatively wide.

5. Photoelectric switch control, only need manual bagging, bag mouth clean, easy to seal, which proves its simple operation, high degree of automation.

Almost all of the powder filling machine in contact with the material parts are made of stainless steel, which can prevent cross contamination and easy to clean.

Of course, if the use of powder filling machine in the process of the phenomenon of the electromagnet does not pull together, mostly due to the host internal failure, electromagnet coil burn out, line interruption and other reasons. To solve this problem, first check whether there is a fault inside the host or outside the host. Then check the electromagnet safety tube, whether the electromagnet has any signs of energization, eliminate mechanical blocking, and then check the internal power supply when everything is normal. If the weighing packaging machine encounters such a failure, it may be that the sensor is damaged, the voltage of the supply bridge is faulty, or the line connection or interruption is wrong. Generally, the load signal of the sensor and the connection line or the host should be detected first, and then the supply bridge and the amplifier circuit or the computer output display circuit should be detected.

Latest News